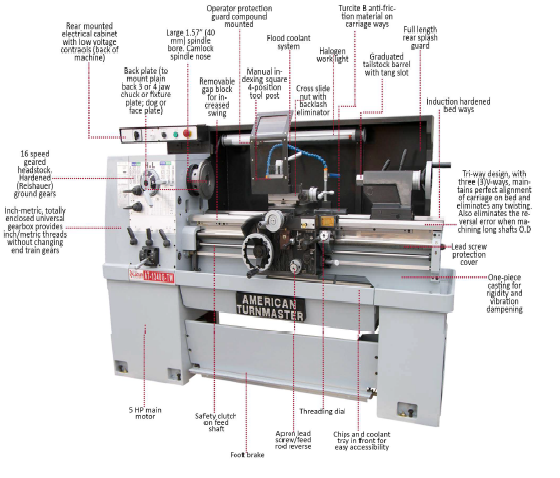

MACHINE SPECIFICATIONS

Model AT-1340-G-TW

Capacity:

Swing over bed 13.39” (340 mm)

Swing over cross slide 8.27” (210 mm)

Distance between centers 39.37” (1,000 mm)

Headstock:

Spindle nose, Cam-Lock D1-4

Spindle bore 1.57” (40 mm)

Spindle speed (Hi-Low) 16 steps

Spindle speed range: STANDARD 50 to 2,570 RPM

Low range 50-80-135-215-315-505-815-1,305

High range 100-160-265-425-625-990-1,600-2,570

Carriage:

Length on bed 15.75” (400 mm)

Width of bridge 15.12” (384 mm)

Cross slide travel 7.09” (180 mm)

Top slide travel 3.94” (100 mm)

Bed:

Number of V ways 3 “V’ ways

Bed width 9.06” (230 mm)

Swing in gap 20.16” (512 mm)

Gap length from faceplate 5.91” (150 mm)

Tailstock:

Quill diameter 1.97” (50 mm)

Quill center M.T.3

Quill travel 4.41” (112 mm)

Feeds and threads:

Range of whit worth threads & No. 2-72 T.P.I. (45)

Range of metric threads & No. 0.2-14 (39)

Range of D.P. & No. 8-44 (21)

Range of M.P. & No. 0.3-3.5 (18)

Longitudinal feed 0.002-0.067” (0.05-1.7 mm)

Cross feeds 0.0009-0.034” (0.025-0.85 mm)

Motor:

Main motor, 2-speed, 3/60/220 V 5 HP (3.73 kW)

Coolant pump 0.12 HP (0.09 kW)

Measurement:

Length packed 89.37” (2,270 mm)

Width packed 38” (965 mm)

Height packed 68.70” (1,745 mm)

Weight:

Gross weight 2,855 lbs. (1,295 kg)

STANDARD EQUIPMENT

Chip and coolant tray

Foot brake

Full length rear splash guard

Compound protection guard (without limit switch)

Manual Indexing Square 4-position tool post

Back Plate (to mount plain back 3 or 4 jaw chuck or fixture plate; dog or face plate) Two (2) No. 3 MT centers and main spindle reduction sleeve

Lead screw protection cover

Halogen work light

Operator protection guard compound mounted

Toolbox and manuals

Leveling pads and bolts

Threading dial

Inch/metric dual dials on cross slide; compound & tailstock

Electrics 220V (STD) /440V (OPTIONAL), 3 phase, 60 Hz (other options available)