DESCRIPTION:

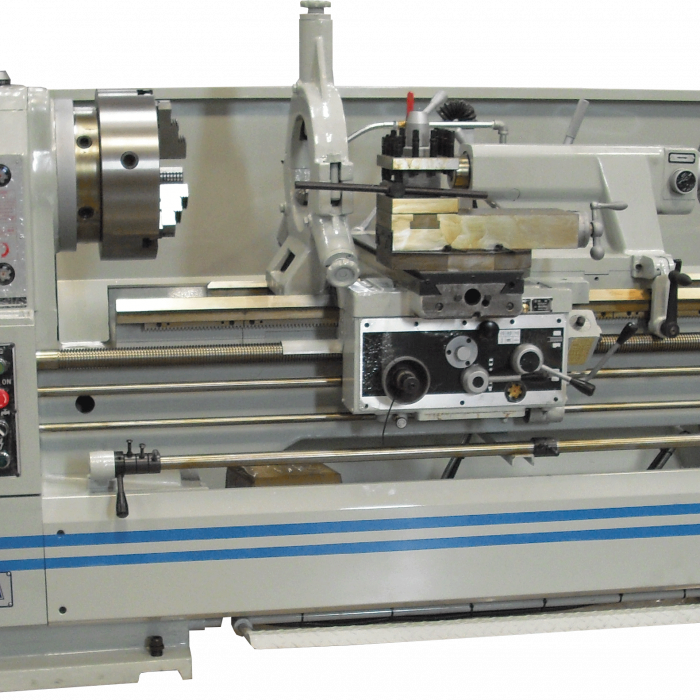

Compact version of MMXL-III. Ideal for small machines with limited installation space.

Specifications

| Pump | Discharge Volume | 1.5〜2.5ml/stroke | |

|---|---|---|---|

| Discharge Pressure | 0.3MPa | ||

| Motor | Voltage / Current | AC100Vφ1/50mA AC200Vφ1/25mA (50Hz) AC100Vφ1/42mA AC200Vφ1/18mA (60Hz) |

|

| Output | 3W Synchronous Motor | ||

| Emergency Detection | Oil level | ||

| Oil Level Switch |

|

||

|

|||

| Operation Rating | Continuous | ||

| Working Viscosity Range | 32〜1300mm2/S | ||

| Reservoir Capacity | 0.8l | ||

| Weight | 1.2kg | ||

| Protection class | IP54 (CE Approved type) | ||

APPLICATION:

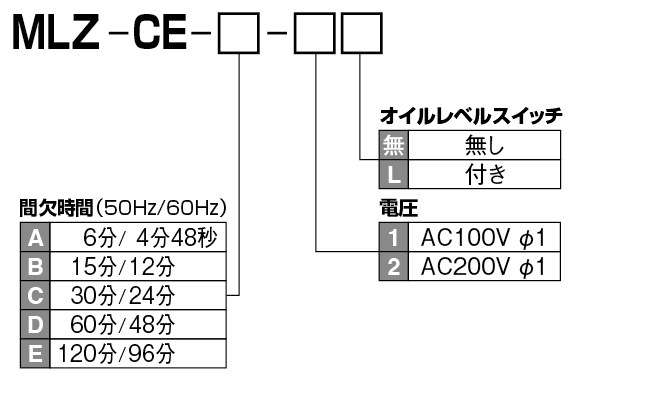

Model

| Model | Part Number |

|---|---|

| MLZ-CE-A-1 | 367201 |

| MLZ-CE-A-1L | 367216 |

| MLZ-CE-A-2 | 367206 |

| MLZ-CE-A-2L | 367221 |

| MLZ-CE-B-1 | 367202 |

| MLZ-CE-B-1L | 367217 |

| MLZ-CE-B-2 | 367207 |

| MLZ-CE-B-2L | 367222 |

| MLZ-CE-C-1 | 367203 |

| MLZ-CE-C-1L | 367218 |

| MLZ-CE-C-2 | 367208 |

| MLZ-CE-C-2L | 367223 |

| MLZ-CE-D-1 | 367204 |

| MLZ-CE-D-1L | 367219 |

| MLZ-CE-D-2 | 367209 |

| MLZ-CE-D-2L | 367224 |

| MLZ-CE-E-1 | 367205 |

| MLZ-CE-E-1L | 367220 |

| MLZ-CE-E-2 | 367210 |

| MLZ-CE-E-2L | 367225 |

Replacement Motor Model

| Interval | 6min. | 15min. | 30min. | 60min. | 120min. | ||

|---|---|---|---|---|---|---|---|

| Mortor RPMrpm (50Hz) | 10 | 4 | 2 | 1 | 1/2 | ||

| Replacement Motor Model | 100V | Model | M-B1 | M-C1 | M-D1 | M-E1 | M-F1 |

| Part Number | 521194 | 521193 | 520062 | 520061 | 520060 | ||

| 200V | Model | M-B2 | M-C2 | M-D2 | M-E2 | M-F2 | |

| Part Number | 521196 | 521195 | 520067 | 520066 | 520065 | ||

Directions for use

| ● | Replace or clean the suction filter at least once a year. Click here to view the service list. |

| ● | Oil viscosity varies with oil temperature. Be sure to use oil within the working viscosity range. Refer to the viscosity table. |

| ● | Do not use any special additive-contained oil, water soluble oil and solvent. |

| ● | Periodically check the oil in the reservoir for impurities. Replace it, if necessary, with fresh oil immediately. Be sure to clean the reservoir before oil change. |

| ● | Make sure that proper voltage and pressure are proper. |

| ● | Do not overtighten the discharge joint. Refer to the tightening torque table. |

| ● | Do not press the discharge volume adjusting knob down by force. |

| ● | Adjust discharge volume only when the piston is fully relaxed ( The knob is at the lowest position.). |

| ● | For system planning information, Contact us. |

Discharge Volume Adjustment

Document

Pump Drawing

Wiring digram

Dimensional Drawing

|

Improper handling can result in a death or serious injury. |

|

Electrical shock may be received under certain conditions.。 |

|

Be sure to ground. |