Overview

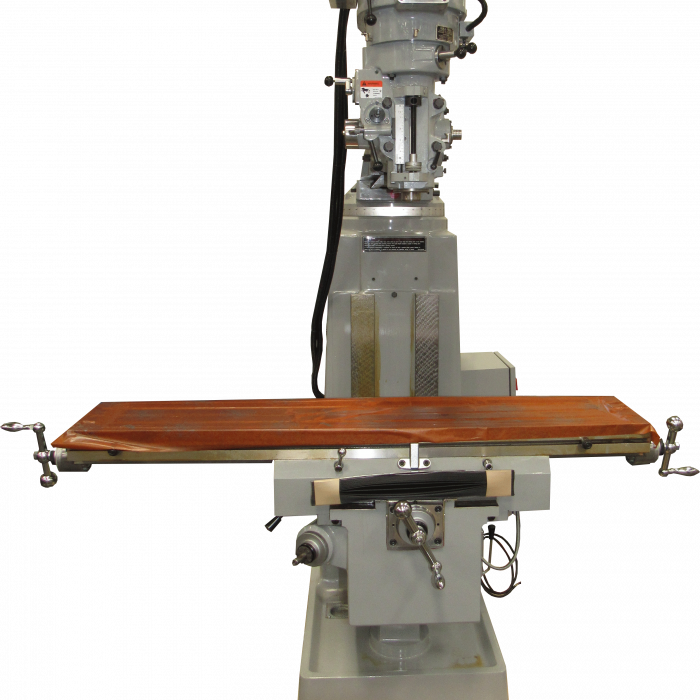

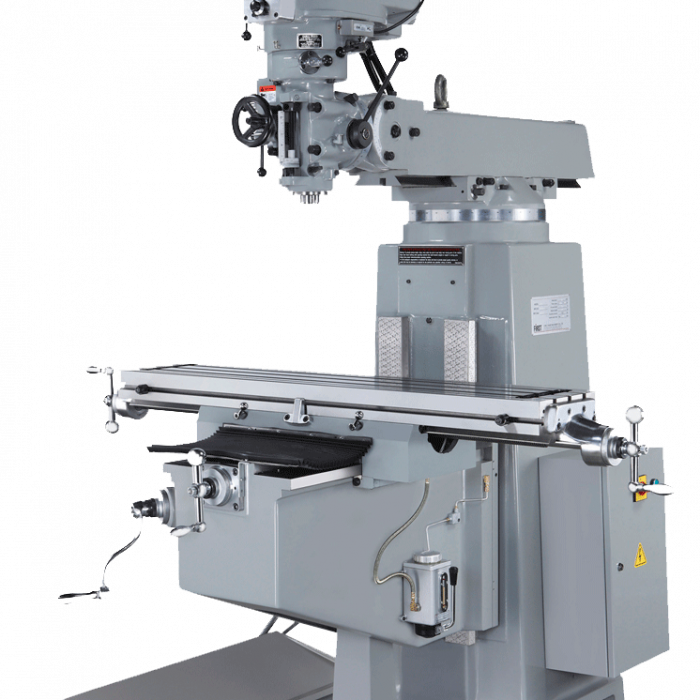

The new all-in-one KMT-6V is a welcome addition to Kingston’s celebrated line of KMT manual turret mills. This fully outfitted milling machine includes special features such as X- and Y-axis power feeds controlled by a Yaskawa frequency inverter drive, longer 54” table, motorized Z-axis auto-knee with rapid function, auto-lubrication, cooling pump & system, coolant & chip pan, halogen worklight, and convenient control box (complete with E-stop button) in order to manage all of the features listed above. The KMT-6V also features a rugged 5 HP motor and a spindle with a Class 7 precision bearing and NT#40 nose—with speeds up to 4,200 RPM and a maximum runout of .0002 inches. The knee and table ways are hardened and ground, while a heavy-duty saddle support runs the full width of the table for extra stability. Kingston’s KMT-6V is strong, reliable, and accessorized.

KMT 6V Special Features

- X & Y-Axis Clutch-Type Auto-Feeds Controlled by Yaskawa Frequency Inverter Drive (180 Parameters)

- 1HP Elevating Motor (Auto-Knee)

- Coolant Pump & System

- Convenient Multi-Function Control Box w/ E-Stop & Special Features Listed Above

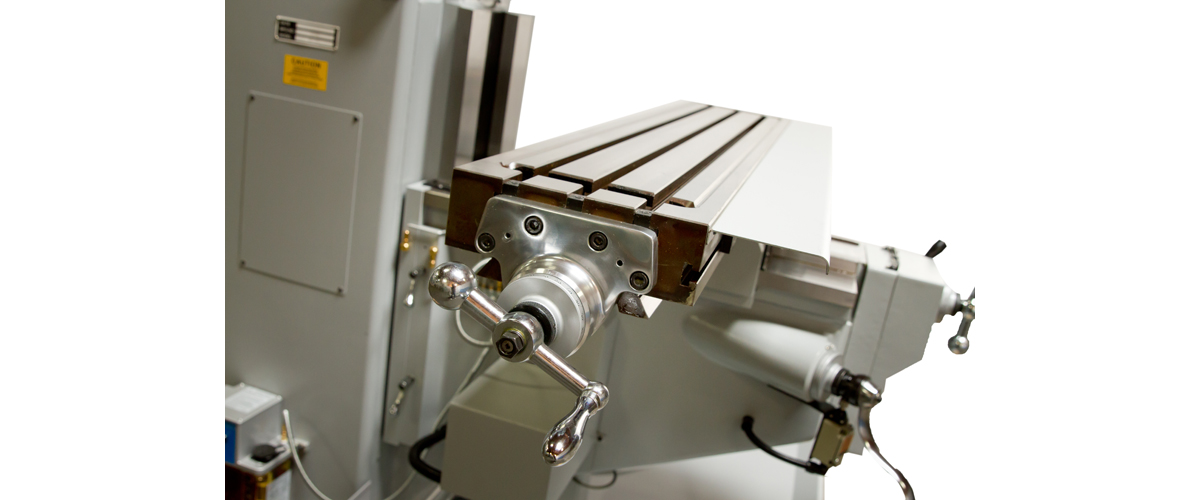

- 10” x 54” Table

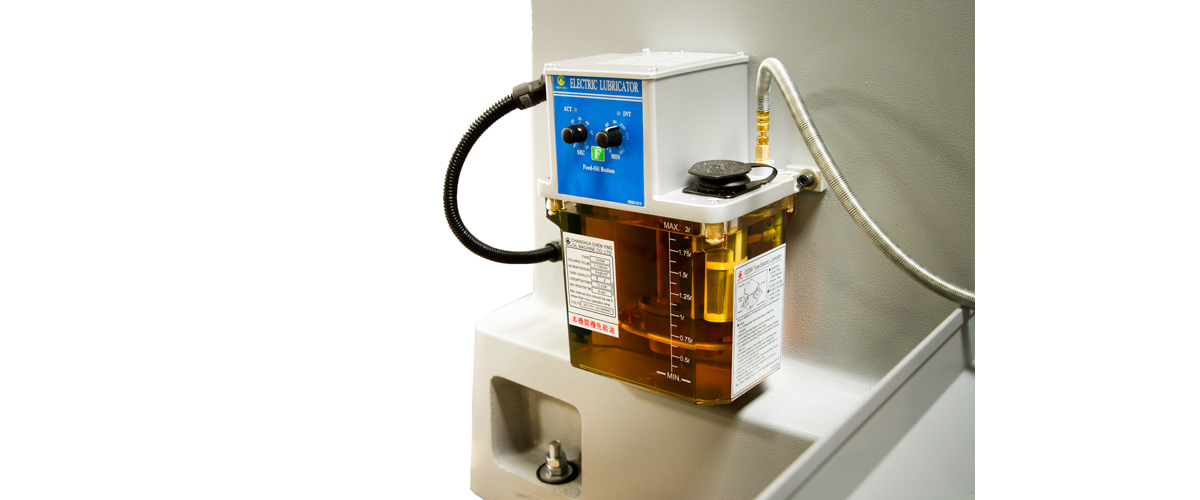

- Auto-Lubrication System (2 Switches)

- Coolant & Chip Pan

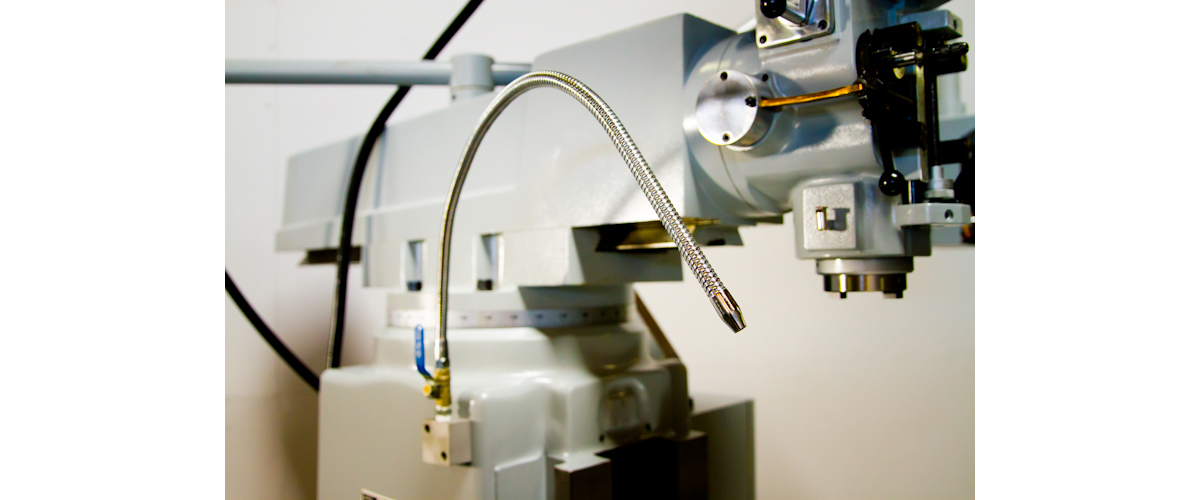

- Halogen Work Light

- Simultaneous X & Z-Axis or Y & Z-Axis Movement Possible

Other Standard Features

- Main Motor: 5HP, 220V only, 3 Phase, 60 Cycle Main

- NT#40 Spindle Nose

- Class 7 Spindle bearings

- Variable speed change (60 – 4200 RPM)

- Chromed Quill

- 3 Quill Feeds Up & Down With Auto Stops

- Max Spindle Accuracy Within .0002” (.0051mm)

- 10” x 54” Hardened & Ground Table

- Square Ways in Both Y & Z Directions

- Hardened & Ground Back Gear & Clutch

- Double Nuts Backlash Eliminator On X+Y Axes

- Double Lock for Table and Knee

- Adjusting Tool & Tool Box

Optional Accessories

- A & T Mechanical Power Lock Drawbar

- Yaskawa Frequency Inverter Drive (Factory Installation Only)

- 2-Axis or 3-Axis Digital Readout (DRO)

| Capacity | |

| Table | 10″ x 54″ |

| Travel (X x Y) | 34.4″ x 15.7″ |

| Travel (Z) Quill | 5.0″ |

| Travel (Z) Knee | 17.5″ |

| Spindle | |

| Spindle Motor | 5HP |

| Spindle Taper | NT#40 |

| Spindle Speed | 60 – 4200 RPM |

| Spindle Power Feed Rate (3 Speeds) | 0.0015″/Rev, 0.003″/Rev, 0.006″/Rev |

| Quill Diameter | 4.1″ |

| Feeds | |

| X- & Y-Axis Feeds | 0 – 1730 RPM |

| Z-Axis (Knee) Feed | 0 – 560 RPM |

| X / Y / Z Motors | 1/2 / 1/2 / 1 HP |

| Dimensions | |

| Overall Height | 93.7″ |

| Overall Length | 60.3″ |

| Overall Width | 74.8″ |

| Weight | 3,740 lbs |