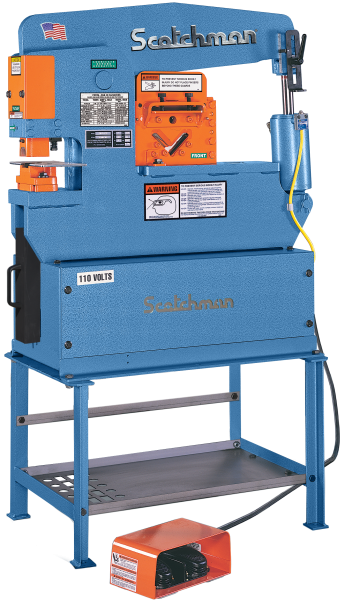

| Single Operator, 7 Stations |

| 50 Ton Punch Station with 3-Station Revolving Turret (1-1/4″ in 1/2″ and 13/16″ in 3/4″) |

| Keyed Punch Ram for Safety |

| 4″ Throat Depth |

| Three 2″ Die Holders, Three Punch Nuts with Wrench and Three Strippers |

| One Round Punch & Die: Max. Dia. 1″ |

| Adjustable Electric Stroke Control with Scale |

| Electric Remote Foot Pedal |

| Angle Shear 4″ x 4″ x 3/8″ at 90° and 2″ x 2″ x 3/8″ at 45° |

| 14″ Flat Bar Shear with 4-Way Reversible Blade (3/4″ x 4″, 1/2″ x 8″, 3/8″ x 10″, 1/4″ x 14″) |

| Rectangular Notcher, 2-1/2″ x 3″ x 5/16″ , 2-1/2″ x 2-3/4″ x 3/8″ |

| Tool Table Work Area |

| Slug Receptacle |

| Electrical Box Supplied with Emergency Palm Button and Lock-out Tag-out Accommodations |

| 230/460 volt /3 Phase Electrics (must specify voltage) |

| All Guards Necessary to Comply with ANSI B 11-5 Standards |

| Forklift Accommodations |

| Warranty: Three Years on Parts |

| Made in USA |

| Rated on: | 65,000 PSI Tensile | A 36 Mild Steel |

| Punching Capacity | 50 ton 1-1/4″ in 1/2″ 13/16″ in 3/4″ |

45 mt 32 mm in 12 mm 21 mm in 18 mm |

| Special Tooling | 2-1/4″ Max. Dia. | 57 mm Max. Dia. |

| Throat Depth | 4″ | 100 mm |

| Flat Bar Shear | 14″ Length 3/4″ x 4″ 1/2″ x 8″ 3/8″ x 10″ 1/4″ x 14″ |

350 mm 18 mm x 100 mm 12 mm x 200 mm 10 mm x 250 mm 6 mm x 350 mm |

| Opt. Saber Blade | 1/2″ x 10″ 3/8″ x 12″ |

12 mm x 250 mm 10 mm x 300 mm |

| Angle Shear 90° | 4″ x 4″ x 3/8″ | 100 mm x 100 mm x 10 mm |

| Angle Shear 45° | 2″ x 2″ x 3/8″ | 50 mm x 50 mm x 10 mm |

| Brake 8″ | 25 ton | 23 mt |

| Brake 12″ | 25 ton | 23 mt |

| Open End Brake | Max. 1/4″ x 3″ Flat or Angle Iron |

(6 x 76 mm) |

| Pipe Notcher Schedule 40 I.D. |

3/4″ 1″ 1-1/4″ 1-1/2″ 2″ |

19 mm 25 mm 32 mm 38 mm 50 mm |

| Rectangle Notcher | 2-1/2″ x 3″ x 5/16″ 2-1/2″ x 2-3/4″ x 3/8″ |

62 mm x 75 mm x 8 mm 62 mm x 69 mm x 10 mm |

| 90° V. Notcher | 6″ x 6″ x 1/8″ 3″ x 3″ x 1/4″ |

150 mm x 150 mm x 3 mm 75 mm x 75 mm x 6 mm |

| Unistrut Shear | Samples Required | |

| Rod Shear Round Rod (Max.) Square Rod (Max.) |

1/4″ to 1″ 5 Cavity 7/16″, 9/16″ 5/8″, 3/4″, 1″ 1/4″ to 3/4″ |

6 mm to 25 mm

11 mm, 14 mm 6 mm to 19 mm 19 mm |

| Square Tube Shear | 1/2″ to 1″ 12 ga. |

12 mm to 25 mm 2.75 mm |

| Picket Tool | 1/2″ 3/4″ 1″ 16 gauge |

12 mm 19 mm 25 mm 1.6 mm |

| Strokes Per Minute in Light Material [Punch Station] | 1/4″ stroke | 40 spm |

| Strokes Per Minute in Heavy Material [Punch Station] | 3/4″ stroke | 17 spm |

| Hydraulics | 2350 psi | 163 bar |

| Motors Standard | 3 hp 3 ph 230/460 208/380/575 |

2.24 kW |

| Motors Optional | 5 hp 1 ph 220v |

3.73 kW |

| Dimensions | W-23″ L-48″ H-70″ |

W-59 cm L-122 cm H-178 cm |

| Shipping Weight | 1,580 lbs | 717 kg |