DESCRIPTION:

Motor driven gear pump for continuous micro-volume lubrication used with a resistance type centralized lubrication equipment.

Specifications

| AMS-1 AMS-3 AMS-6 | |||

| Pump | Discharge Volume | AMS-1:1.25ml/min (50Hz) 1.5ml/min (60Hz) AMS-3:2.5ml/min (50Hz) 3ml/min (60Hz) AMS-6:5ml/min (50Hz) 6ml/min (60Hz) |

|

|---|---|---|---|

| Discharge Pressure | 0.8MPa (safety valve set pressure) | ||

| Motor (Other voltages available.) |

Voltage / Current | AC100Vφ1/50mA AC200Vφ1/25mA (50Hz) AC100Vφ1/42mA AC200Vφ1/18mA (60Hz) AC100Vφ1/25mA AC200Vφ1/18mA (60Hz) |

|

| Output | 3W Synchronous Motor | ||

| Emergency Detection | Oil level | ||

| Oil Level Switch |

|

||

|

|||

| Operation Rating | Continuous | ||

| Working Viscosity Range | 32〜1300mm2/S | ||

| Reservoir Capacity | 1.8l、3l (plastic) 3l、4l、8l (sheet metal) | ||

| Weight | 1.8kg | ||

| AMS-15 | |||

| Pump | Discharge Volume | 15ml/min (50Hz) 18ml/min (60Hz) | |

| Discharge Pressure | 0.8MPa (safety valve set pressure) | ||

| Motor (Other voltages available.) |

Voltage / Current | AC100Vφ1/0.25A (50/60Hz) 200Vφ1 | |

| Output | 5.0W Condesor3.0μF_ Accessory | ||

| Gear Head | Speed Reduction Ratio: 1/25 | ||

| Working Viscosity Range | 32〜1300mm2/S | ||

| Reservoir Capacity | 1.8l、3l (plastic) 3l、4l、8l (sheet metal) | ||

| Weight | 2.3kg | ||

APPLICATION:

Model

| Model | Part Number |

|---|---|

| AMS-1-1 | 102401 |

| AMS-1-1L | 102403 |

| AMS-1-2 | 102402 |

| AMS-1-2L | 102404 |

| AMS-15-1 | 102416 |

| AMS-15-1L | 102418 |

| AMS-15-2 | 102417 |

| AMS-15-2L | 102419 |

| AMS-3-1 | 102405 |

| AMS-3-1L | 102407 |

| AMS-3-2 | 102406 |

| AMS-3-2L | 102408 |

| AMS-6-1 | 102489 |

| AMS-6-1L | 112094 |

| AMS-6-2 | 102490 |

| AMS-6-2L | 112095 |

Replacement Motor Model

| Pump | Part Number | Voltage | Replacement Motor Model |

|---|---|---|---|

| AMS-1 | 521194 | 100V | M-B1 |

| 521196 | 200V | M-B2 | |

| AMS-3 | 521194 | 100V | M-B1 |

| 521196 | 200V | M-B2 | |

| AMS-6 | 521210 | 100V | M-A1 |

| 521328 | 200V | M-A2 |

Directions for use

| ● | Replace or clean the suction filter at least once a year. Click here to view the service list. |

| ● | Oil viscosity varies with oil temperature. Be sure to use oil within the working viscosity range. Refer to the viscosity table. |

| ● | Do not use any special additive-contained oil, water soluble oil and solvent. |

| ● | Periodically check the oil in the reservoir for impurities. Replace it, if necessary, with fresh oil immediately. Be sure to clean the reservoir before oil change. |

| ● | Make sure that proper voltage and pressure are proper. |

| ● | Do not overtighten the discharge joint. Refer to the tightening torque table. |

| ● | For system planning information, Contact us. |

Document

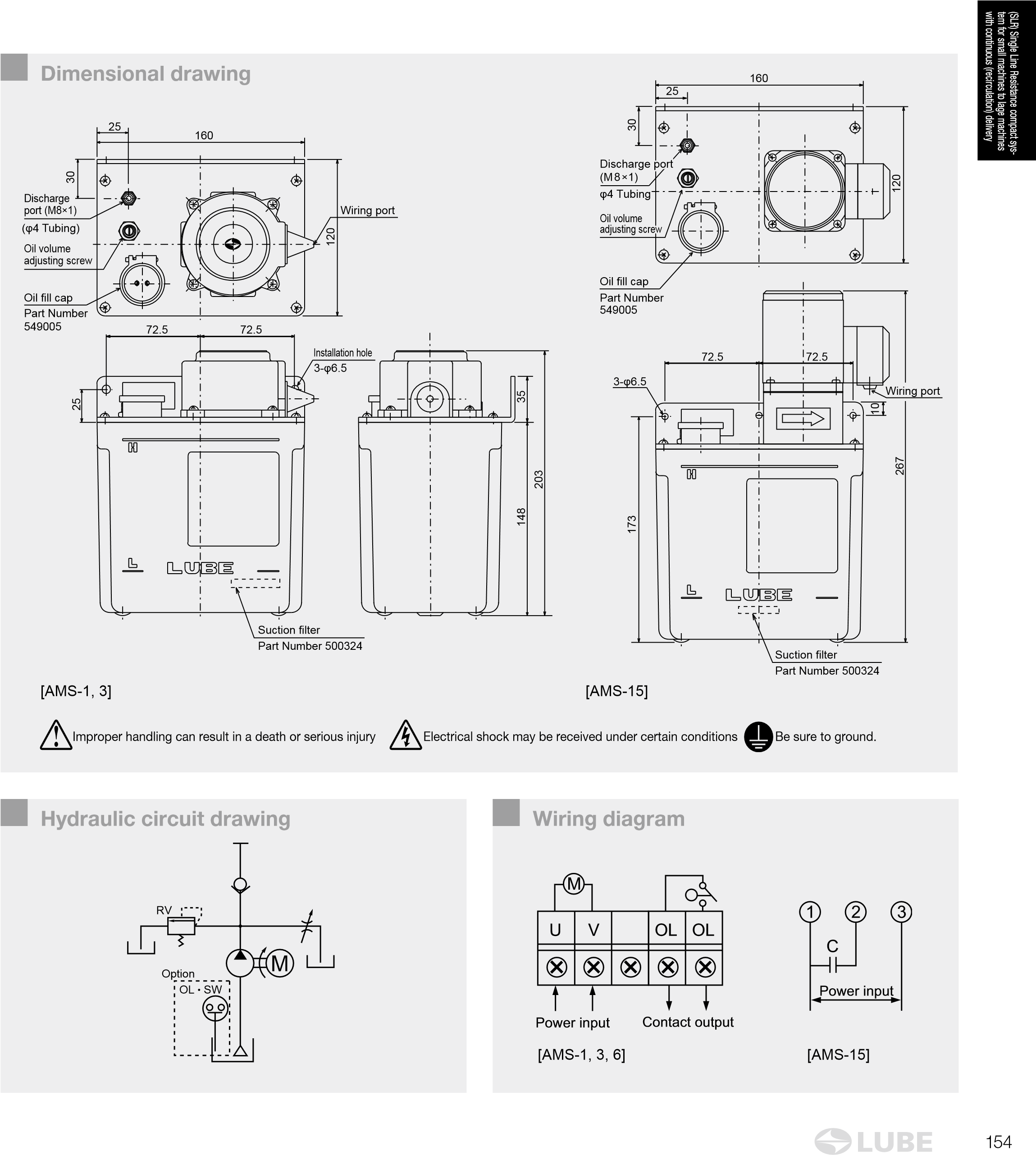

Pump Drawing

Wiring digram

Dimensional Drawing

|

Improper handling can result in a death or serious injury. |

|

Electrical shock may be received under certain conditions.。 |

|

Be sure to ground. |