<strong>Specifications:</strong>

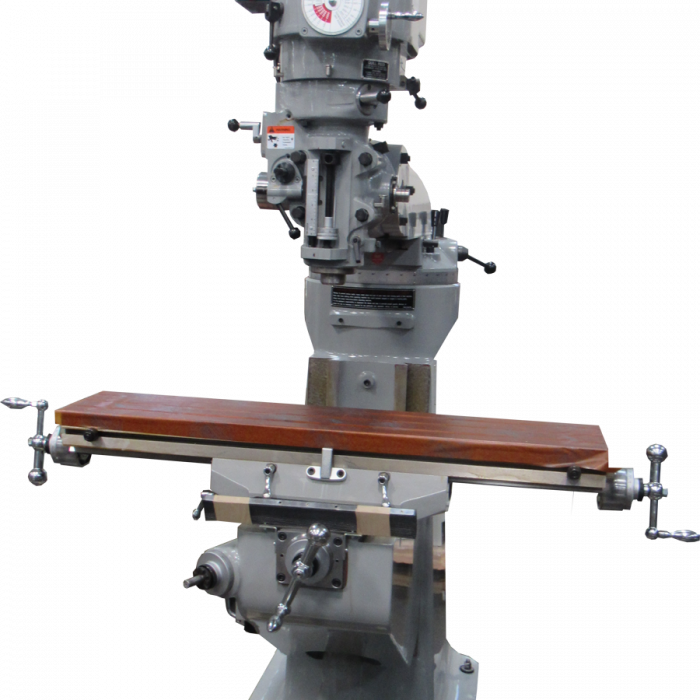

Table Size: 9″ X 42″

X Axis Travel: 30″

Y Axis Travel: 12″

Z Axis Travel: 5″

T-Slots: 3 x 0.625″ x 2.5″

Ram Travel: 12″

Knee Travel: 16″

Throat Distance: 6.75″ ~ 18.75″

Spindle to Table Top: 0 ~ 18.5″

Main Motor: 3 HP

Spindle Nose: R-8 or #30 NST

Spindle RPM: 60 – 4,500 RPM

Quill Feeds: 0.0016″/0.0031″/0.0063″

Voltage: 230/460V AC~3 PH

<strong>Standard Equipment</strong>

Quill Heat Treated, Hardened & Chromed

One Shot Lubrication

Emergency Stop

Call for Price

<ul>

<li>Main Motor: 5HP, 220V only, 3 Phase, 60 Cycle Main</li>

<li>NT#40 Spindle Nose</li>

<li>Class 7 Spindle bearings</li>

<li>Variable speed change (60 – 4200 RPM)</li>

<li>Chromed Quill</li>

<li>3 Quill Feeds Up & Down With Auto Stops</li>

<li>Max Spindle Accuracy Within .0002” (.0051mm)</li>

<li>10” x 54” Hardened & Ground Table</li>

<li>Square Ways in Both Y & Z Directions</li>

<li>Hardened & Ground Back Gear & Clutch</li>

<li>Double Nuts Backlash Eliminator On X+Y Axes</li>

<li>Double Lock for Table and Knee</li>

<li>Adjusting Tool & Tool Box</li>

</ul>

Call for Price

<strong>Outstanding Features</strong>

<ul>

<li>The new FTV-2F model comes standard with 5” (127 mm) more table length and 5.5” (139 mm) more table travel than our previous FTV-2.</li>

<li>Mechanical infinite variable speed head</li>

<li>Providing full HP at all RPM’s</li>

<li>R-8 spindle taper</li>

<li>Square ways for rigidity and dovetail ways for accuracy</li>

</ul>

Call for Price

<ul style="list-style-type: circle">

<li>3 HP spindle motor, variable speed milling head with AC-Frequency drive, digital RPM display, analog load meter, and automatic spindle direction reversal when switching between high & low speed ranges</li>

<li>9” x 49” hardened and ground table top</li>

<li>T-slots ground parallel to table ways</li>

<li>Table, saddle, and knee with hardened and ground dovetail ways</li>

<li>Precision ground leadscrews with backlash compensating double nut</li>

<li>Precision bored and ground milling head, with super precision ABEC-7 bearings</li>

<li>Meehanite® casting, with built in coolant reservoir in machine base</li>

<li>Automatic lubrication, with metered check-valves</li>

</ul>

Call for Price