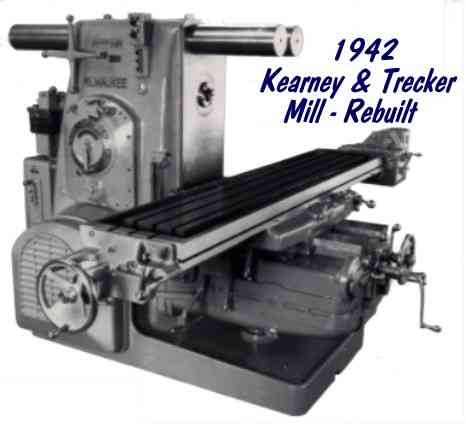

Our Methods of Rebuilding Your Machine Tools

Mill Rebuilding

After years of hard use, the milling machine above began to show signs of major wear and could no longer maintain the accuracy required for meeting today's higher machining standards. To restore it to its original precision and performance, a complete rebuild was necessary.

- Step 1 Machine is completely disassembled, steam cleaned and inspected.

- Step 2 All parts are repaired or replaced with the customer's approval.

- Step 3 The knee, saddle and gibs are machined to remove score marks.

- Step 4 Top of the table is ground.

- Step 5 Entire machine is hand scraped and realigned.

- Step 6 All bearings, bushings and seals are replaced.

- Step 7 Electrical system, lubricating system and coolant system are updated.

- Step 8 Machine is reassembled and test run.

- Step 9 Machine is filled, sanded, and custom painted.

- Step 10 All handles and dials are chromed.

- Step 11 Customer makes final inspection and gives approval for shipping.

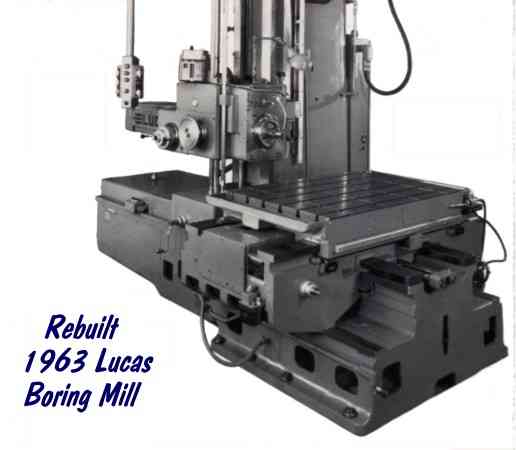

Alignment Rebuilds

The milling machine above ran properly, but had difficulty maintaining accuracy. In this case, an alignment was all that was necessary to restore it to its original specifications. This particular machine had hardened ways, therefore grinding was necessary to achieve proper alignment.

- Step 1 The machine is disassembled to the extent necessary to accomplish the following:

- Step 2 The base, top of the saddle, and the column are reground to factory specifications.

- Step 3 The head, bottom the the saddle, and the top and bottom of the table are handscraped for proper fit and alignment.

- Step 4 The gibs are machined to remove score marks, then handscraped for proper fit and alignment.

- Step 5 Where applicable, nonmetallic inserts are installed.

- Step 6 Both the electrical system and lubricating system are updated.

- Step 7 Machine is reassembled and test run.

- Step 8 Machine is filled, sanded, and custom painted.

- Step 9 Customer makes final inspection and approves for shipping.